音速文丘利喷嘴家用煤气表检定装置

煤气表检定装置

煤气表检定装置 天然气表检定装置(全自动)

21世纪计量(计量检测中心)销售热线:15914142916

| 设备名称 | 主要参数及精度 | 备注 |

| 钟罩式气体流量标准装置 | 100L 0.5级 | 安装后检定合格 |

| 检定工作台 | 手动夹表 | 三表位,不锈钢 |

| 密封性试漏装置 | 自带加气泵,干式 | 三表位,不锈钢 |

| 压力补偿及压损检测系统 | 压力分辨率:10Pa | 压力:测四点,四个微低压压力变送器(1151、3051) |

| 检定系统管理软件 可实现容量、温度、压力检测数据的自动采集,进行各项数据处理,检定数据及检定证书的保存与打印 | ||

| 检定系统硬件及配电控制 | ||

| 计算机,激光打印机 | ||

JRB1.6JRB2.5型煤气表

四、规格及主要技术参数 1、使用环境温度:-5℃~40℃ 2、外接电源电压:6V 3、掉电保护电压:2.78V 4、静态工作电流:<3μA

型号 | 公称流量 Qn(m3/h) | 最大流量 Qmax(m3/h) | 最小流量 Qmin(m3/h) | 最大工作压力 | 基本误差 | 最大累计读数 (m3) | 总压力损失 (Pa) | 中心距离 (mm) | |

Qmin≤Q≤0.1max | 0.1max≤Q≤Qmax | ||||||||

CG-L-J RB1.6 | 1.6 | 2.5 | 0.016 | 10 | ±3% | ± 1.5% | 99999.9 | ≤ 250 | 130 |

CG-L-J RB2.5 | 2.5 | 4.0 | 0.025 | ||||||

RF-L-2.5W煤气表

| |||||||||||||||||||||||||||

32M217176家用煤气表(普通) 型号:32M217176

| 家用煤气表(普通) 型号:32M217176 | |

| 用途:煤气表分别适用于人工煤气、天然气、液化石油气、沼气等燃气流量的计量。 性能:计量、安装简单、维修方便,具有防逆装置,采用钢材外壳和特殊的表面处理技术,耐腐蚀能力强,使用寿命长。 结构:本系列煤气表属于膜式结构,由外壳、机芯、计数器三部分组成。 安装、使用说明 1、 煤气表左侧为进气口,右侧为出气口,安装时不得接反。 2、 用户安装时,应对照技术性能表中不同型号煤气表表接头螺纹尺寸及其间距,来选配联接弯管。 3、 煤气表安装后,禁止用明火在管道上检漏,禁止充入氧气及易燃易爆或其它有毒有害气体试漏。 4、 安装时煤气表进气口一侧须安装阀门一只,在必要时可关闭燃气。 5、 煤气表应安装在干燥通风的地方,其温度要求一般应在0-40之间,其安装位置应远离火种,严禁装入卧室。发生漏气时,应关闭阀门,敞开门窗,修表时也应将表拆下,方可修理。 6、 流经煤气表的气体就应当干净,无大颗粒的固体杂质及粘性很大的沾污物,以防损坏煤气表。 7、 煤气表在运输存放中,应保持直立,不得倒置或摔碰。 尺寸:210*174*266*130(mm) 重量:净重(2.5kg),包装重{(5kg),一个箱子里装2个}包装尺寸:210*350*285mm G系列家用煤气表主要技术指标 项目ltem 单位 流量Q n M3/h 1.6 最大流量Q max M3/h 2.5 最小流量Q min M3/h 0.016 最大工作压力Working pressure rnax kpa 20 总压力Total pressure losses pa ≤200 基本误差Basic error Q min≤Q<0.1 Qmax % ±3 0.1Qmax≤Q≤Qmax % ±1.5 接头螺纹Connector’s thread M 30×2 接头中心距connector’central diastance mm 130 最大累计读数Aeeumulative reading max M3 99999 | 产品图片  |

IC卡煤气表电磁阀

结构特点 电磁阀采用双稳态结构型式,瞬时通电即可保持工作状态。直流正向得电阀开通,反向得电阀关闭。

主阀与导阀之间设有特殊的隔离膜片,能阻挡燃气及杂质进入导阀腔,延长了使用寿命且动作更,本结构受专利保护.

经国家防爆站检测,导阀线圈总成符合GB3836.4-83防爆标准,取得了防爆合格证,证号为GYB98515U 产品用途:与IC卡煤气表配套,用作燃气管道的二位式通断切换;也可作为CO熄火保护报警器及大容量燃气热水器配套使用.

燃气表MID认证/煤气表CE认证

美国 Meriam M201 旋转式煤气表测试仪(价格优惠)

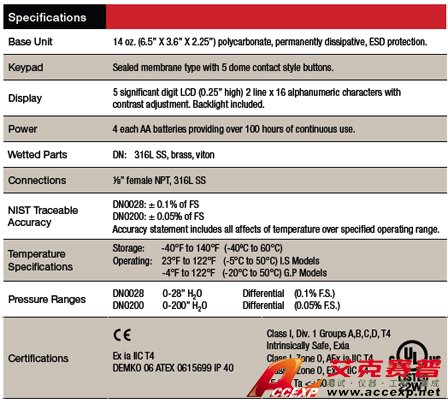

美国 Meriam M201 旋转式煤气表测试仪的详细介绍The new Measure Mode lets the M201 be used as a conventional differential pressure measurement device. Users will appreciate the live pressure display as they check the handheld’s zero or observe DP across rotary gas meters. And when a drop test is made, the M201 uses an internal stop watch to measure the test length. The user only has to start and stop the test; the M201 reports both the test time and the average differential pressure measured during the test. Toggle the Min/Max key to see the minimum and maximum DP measured during the test.Meriam’s M201 has new features to make drop testing Rotary (Natural) Gas Meters even easier! New hardware options protect the M201 from one sided overpressure. Options include a ¼ turn valve manifold and an integral push-to-read cartridge valve in addition to the traditional push-to-read valve manifold. More importantly, new operating features provide users with a live pressure display and more automation to make field use easier than ever before.With hundreds of original M201s at work in the field, Meriam recognizes that some customers will want to continue using the legacy software to stay consistent within their company. The new M201 includes a Mode Selection menu option for Legacy or Enhanced modes – the users chooses which mode is best for them!Rotary Gas Meter Tester M201 AdvantagesAccuracyDN0028: ±0.1% FS 0-28”DN0200: ±0.05% FS 0-200”No temperature effect from 23º to 122ºF (-5º to +50ºC).Engineering UnitsInches of H2O (select 4ºC, 20ºC, or 60ºF), PSI, mm of Hg, inches of Hg, mBars, Bars, kPa, kg/cm2, cm of H2O and user selectable scaling.Media CompatibilityDN: Non-isolated differential sensor for clean, dry, non-corrosive gases.Field Re-calThe M201 can be recalibrated in the field for zero, span, and linearity. The user has the option to select a 1 point or 5 point calibration procedure. Enables users with accurate primary standards to calibrate their devices locally if desired.Pressure LimitsTwice range on Differential (DN) units when pressurized on high side only and 150 PSI (10.5 Kg/cm2) static when applied to both sides of the sensor simultaneously.Min/Max CaptureCapture speed is 10X per second.OperationEnchanced - A push-to-read or 1/4 valve assembly keeps HI and LO sides equalized during connection across meter. Turn M201 "ON" to get message "Press Hold to Acquire Data." Press "Hold" key to start test. User determines test time, ending test by pressing the "Hold" key again. Display will show the test time and averaged differential pressure across the meter during the test. Press the "Hold" key again to start a new test. Legacy - A push-to-read valve keeps HI and LO sides equalized during connection across meter. Turn M201 "ON" to get message "Press Hold to Acquire Data." Press "Hold" key to start test. User determines test time, ending test by pressing the "Hold" key again. Display will show the averaged differential pressure across the meter from test start to test stop. Press the "Hold" key again to start a new test. Auto Shut-OffUser selectable shut-off. Programmable at 10, 20, 30, 45, 60 minutes and disable. Ordering InformationModel Number & DescriptionM201 (specify pressure range) Rotary Gas Meter Tester (only available with DN0028 or DN0200 sensor range)Specify valve type: PTR (Push-to-Read Assembly) IPTR (Integral Push-to-Read Valve) QTV (1/4 Turn Valve Assembly)All Models Include• Protective Red Boot• 4 AA Alkaline batteries• Hard copy user’s manualOrder Options Z9A000069 Hard Carrying Case Z9P000108 Hard Carrying Case with Vacuum Pump Z9P000109 Hard Carrying Case with Pressure Pump ZA34386 Connector Kit ZA900016-90727 Pete’s Plug Adapter Kit Y 1/8” Needle ZA900016-90733 Pete’s Plug Adapter Kit Y 1/16” NeedleZA36853 Push-to-Read ManifoldZ9A000001 Integral Push-to-Read ValveZ9A156 1/4 Turn Valve ManifoldThe digital display eliminates parallax errors, and depending on the range of the gauge, it can have a resolution of 0.01 or 0.001” H2O. A min/max feature also allows the user to see the minimum and maximum pressures recorded during the test. The unit is portable, and with the integral push to read manifold, the M201 Rotary Gas Meter Tester can safely be used with lines having a static pressure of up to 150 PSIG.

Ordering InformationModel Number & DescriptionM201 (specify pressure range) Rotary Gas Meter Tester (only available with DN0028 or DN0200 sensor range)Specify valve type: PTR (Push-to-Read Assembly) IPTR (Integral Push-to-Read Valve) QTV (1/4 Turn Valve Assembly)All Models Include• Protective Red Boot• 4 AA Alkaline batteries• Hard copy user’s manualOrder Options Z9A000069 Hard Carrying Case Z9P000108 Hard Carrying Case with Vacuum Pump Z9P000109 Hard Carrying Case with Pressure Pump ZA34386 Connector Kit ZA900016-90727 Pete’s Plug Adapter Kit Y 1/8” Needle ZA900016-90733 Pete’s Plug Adapter Kit Y 1/16” NeedleZA36853 Push-to-Read ManifoldZ9A000001 Integral Push-to-Read ValveZ9A156 1/4 Turn Valve ManifoldThe digital display eliminates parallax errors, and depending on the range of the gauge, it can have a resolution of 0.01 or 0.001” H2O. A min/max feature also allows the user to see the minimum and maximum pressures recorded during the test. The unit is portable, and with the integral push to read manifold, the M201 Rotary Gas Meter Tester can safely be used with lines having a static pressure of up to 150 PSIG.

最新产品

- 人睾酮(T)ELISA试剂盒 2025/1/3 13:06:12

- 人高铁血红蛋白(HMB)ELISA试剂盒 2025/1/3 13:04:15

- 人高迁移率族蛋白B1(HMGB-1)ELISA试剂盒 2025/1/3 13:02:30

- 校园气象站设备 2025/1/3 13:01:13

- 人高密度脂蛋白胆固醇(HDL-C)ELISA试剂盒 2025/1/3 13:01:09

- 农业虫情测报系统 2025/1/3 13:00:19

- 人高密度脂蛋白(HDL)ELISA试剂盒 2025/1/3 13:00:16

- 微气象监测系统 2025/1/3 12:59:24

- 便携式全自动气象站 2025/1/3 12:58:07

- 人高尔基体蛋白73(GP73)ELISA试剂盒 2025/1/3 12:58:04

- 人高尔基糖蛋白1(GLG1)ELISA试剂盒 2025/1/3 12:56:29

- 人干细胞因子受体(SCFR)ELISA试剂盒 2025/1/3 12:55:43

- 天然氧吧监测站 2025/1/3 12:55:15

- 人干细胞因子(SCF)ELISA试剂盒 2025/1/3 12:53:59

- 人干扰素诱导蛋白4(IFIT4)ELISA试剂盒 2025/1/3 12:52:42

- 人干扰素诱导蛋白10(IP-10;CXCL10)ELISA试剂盒 2025/1/3 12:51:52

- 人干扰素诱导蛋白10(IP-10)ELISA试剂盒 2025/1/3 12:50:20

- 人干扰素诱导T细胞趋化因子(ITAC;CXCL11)ELISA试剂盒 2025/1/3 12:48:19

- 人干扰素调节因子5(IRF5)ELISA试剂盒 2025/1/3 12:46:54

- 人干扰素调节因子4(IRF4)ELISA试剂盒 2025/1/3 12:45:31

- 人干扰素调节因子(IRF)ELISA试剂盒 2025/1/3 12:44:29

- 人肝脂酶(HL)ELISA试剂盒 2025/1/3 12:42:24

- 人肝脂肪酸结合蛋白(LFABP)ELISA试剂盒 2025/1/3 12:41:36

- 人肝脂肪酸结合蛋白(FABP1)ELISA试剂盒 2025/1/3 12:40:04

- 人肝细胞生长因子受体(HGFR)ELISA试剂盒 2025/1/3 12:38:11

- 人肝细胞核因子4α(HNF4α)ELISA试剂盒 2025/1/3 12:34:50

- 人肝细胞癌结合蛋白TD26(TD26)ELISA试剂盒 2025/1/3 12:33:02

- 人肝素辅因子Ⅱ(HCⅡ)ELISA试剂盒 2025/1/3 12:31:07

- 人肝配蛋白B3(ephrin-B3)ELISA试剂盒 2025/1/3 12:29:11

- 人肝癌衍生生长因子(HDGF)ELISA试剂盒 2025/1/3 12:28:06